IR News

Hoshizaki Applies IoT to Equipment to Help Raise Management and Work Efficiency

Easy to Introduce with Wi-Fi Modules and SaaS

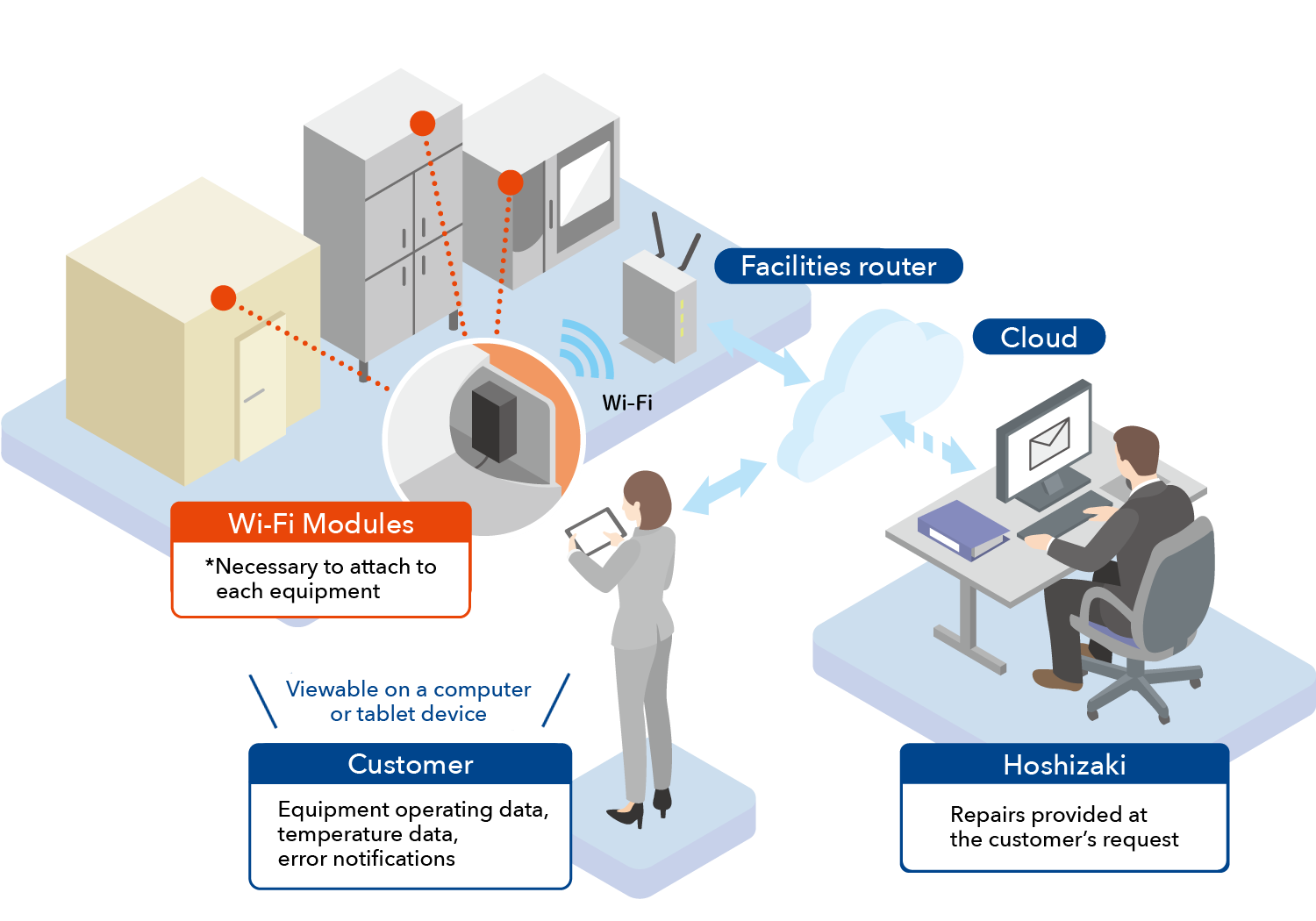

HOSHIZAKI CORPORATION (Head office: Toyoake City, Aichi; President & COO: Yasuhiro Kobayashi; hereafter “Hoshizaki”) will begin providing Hoshizaki Connect Wi-Fi in Japan on January 5, 2024 through its sales companies. Hoshizaki Connect Wi-Fi is a new service (SaaS1) that attaches a Wi-Fi module to equipment like commercial refrigerators and allows operating and temperature data to be managed by cloud servers. By making IoT on equipment free of any initial charges2, Hoshizaki is helping customers operate efficiently.

Service Diagram

Using the SaaS developed proprietarily by Hoshizaki, customers will be able to confirm, manage, and record in real time the operating status and temperature of multiple equipment in multiple locations on a computer, tablet, or other device over the internet anytime and anywhere. Wi-Fi modules that attach to each equipment will be provided and installed free of charge, so the initial cost is zero. A service fee of ¥1,000 per equipment per month (before tax) will be charged and the number of equipment that may be connected is at least one and there is no upper limit.3 Customers using Hoshizaki Connect Wi-Fi are allowed to freely set the number of users, viewing and management authorization, alarm notification conditions, and where error notifications are sent when generated by the equipment.

The service is eligible with Hoshizaki commercial refrigerators and other major products, including products already sold, and the company plans to steadily expand the scope. The temperature management service may even be eligible with the products of other companies if another device is installed.

The company is aiming to deploy the system where benefits such as integrated management and HACCP4 compliance via IoT can be expected, including at supermarkets, convenience stores, restaurant chains and other customers that manage multiple stores and facilities, as well as facilities like hospitals, meal providers, and hotels that prepare large amounts of food, and distribution centers.

■Lowering the barrier to introduction by combining a Wi-Fi module and SaaS

Hoshizaki is already providing Hoshizaki Smart Band and Hoshizaki Smart Band Cloud as a temperature management service in line with the Manual for Hygiene Management at Large-Scale Food Preparation Facilities put out by the Ministry of Health, Labour and Welfare based on the HACCP concept. However, there are initial costs in both cases and they require a dedicated router and fixed line, which have been issues.

Hoshizaki Connect Wi-Fi, however, does not require communications wiring work at the installation site as long as there is a Wi-Fi environment, and there are no initial costs, so it is easy for customers to introduce. Additionally, it can manage not just temperature but equipment operating status as well.

■Software improved based on big data obtained through demonstration experiments

Hoshizaki has held demonstration experiments since September 2022 on around 1,700 pieces of equipment, including Hoshizaki commercial refrigerators and steam convection ovens in operation at customer sites.

Based on the big data and results of the demonstration experiments, the software was improved to prevent inadequate temperature control when a breakdown would go untreated and to rein in excessive electricity usage. Through the experiments it was found that the system contributes greatly to customers by sending alerts of abnormal high temperatures after stores have been closed to prevent food waste and the risk of food poisoning and also by lowering the administrative burden thanks to automatic creation of various forms.

■Benefits of introducing Hoshizaki Connect Wi-Fi

Support for efficient equipment operations through integrated management

For customers that manage multiple stores or facilities, integrated management makes for efficient operations as equipment operating status is grasped for the organization as a whole. For example, previously errors issued by equipment could not be known until the actual equipment display could be seen, but they can now be verified remotely. With refrigerators and freezers, the lower the temperature setting, the more electricity is used, so using the system the customer can verify and manage differences in temperature settings among stores and facilities to set temperatures for higher energy efficiency, which are displayed onsite.

Save manual labor via automated recording

Rendering of form creation screen

Food-related providers are required by law to create certain forms. They are required to create a fluorocarbon inspection form under the Act on Rational Use and Appropriate Management of Fluorocarbons, and since June 2021 they have been required to record and save sanitation management records in line with HACCP under the revised Food Sanitation Act. These forms are often handwritten or manually inputted, so the administrative burden is significant.

By introducing Hoshizaki Connect Wi-Fi, temperature forms and fluorocarbon management inspection forms, which have been handwritten or entered manually, are provided automatically in a spreadsheet format that is accessible by simply clicking a button on the screen.

Use operating data to detect potential trouble; response available at the customer’s request

By setting figures related to potential breakdowns based on its technical knowledge, Hoshizaki has created a system that allows for automatic breakdown detection. Operating data is shared with Hoshizaki, so at the customer’s request, the company can respond quickly when a breakdown occurs or make improvement proposals for trouble that is difficult for the customer to notice, like gasket deterioration. When the customer requests onsite maintenance, Hoshizaki can grasp the situation in advance based on the data, so cases that would require two visits before, one to grasp the situation and one to make the repairs, can be completed in a single visit, which speeds up the response.

Hoshizaki is positioning this service as a new business for expanding conventional maintenance services. In the future, the company will endeavor to provide new value and expand services by promoting DX5 with a view to utilizing AI to analyze accumulated data.

1: Software as a Service. Software provided by a service provider that can be used over the internet without being installed.

2: As long as the site where the service is to be introduced has a device that can be connected to the internet, and a Wi-Fi environment that does not require a relay, Wi-Fi modules to be installed on Hoshizaki’s equipment eligible for the service are provided and installed free of charge and the first month’s usage fee is waived.

3: The number of equipment that allow data to be collected by Hoshizaki. The number that can be installed at each site depends on the Wi-Fi router specifications.

4: Hazard Analysis and Critical Control Point. According to the Ministry of Health, Labour and Welfare, it is a sanitation management method to ensure the safety of products by the food provider itself grasping hazards like food poisoning and admixture of foreign substances and managing particularly important processes for removing or reducing these hazards in all processes, from reception of raw materials to shipment of the product. This method was announced by a joint food regulation committee (Codex Alimentarius Commission) of the UN Food and Agriculture Organization (FAO) and the World Health Organization (WHO).

5: Digital transformation. In the Digital Governance Code 2.0 of the Ministry of Economy, Trade and Industry, it is defined as a course of action by companies responding to abrupt changes in the business environment, utilizing data and digital technologies, reforming products, services, and business models based on customer and societal needs, and changing operations, organizations, processes, and corporate culture and climate, to thereby establish a competitive advantage.