IR News

Hoshizaki Launches its First Liquid Freezer

Expanding the horizons of frozen food to meet demand for prepared meals and helping to solve food-related industries’ issues.

HOSHIZAKI CORPORATION (Head office: Toyoake City, Aichi; President & COO: Yasuhiro Kobayashi; hereafter “Hoshizaki”) has developed its first liquid freezer and will launch two models through its sales companies on December 18.

Liquid Freezer HLF-2A and HLF-3A

■Growing demand for prepared meals, labor shortages and food waste issues in food-related industries

Against the backdrop of food diversification, changes in lifestyles and family structure, and the aging population, the size of the prepared meal market, one section of the food market alongside the home-cooked meal1and dining-out markets, continues to grow2. The size of the home-use frozen food market exceeded that of the commercial frozen food market in both volume and value in 2021 and reached 800,000 tons and 406.1 billion yen3 in 2022. This trend has led to the popularization of the expression “second freezer” in Japan as more and more households install additional freezers in their homes. Demand for prepared meals, including frozen foods, is expected to remain strong even in post-COVID times.

Meanwhile, in the food-related industry as a whole, there is constant need for higher efficiency and productivity as a response to severe labor shortages. Initiatives for the reduction of food waste have become a common challenge throughout the entire industry.

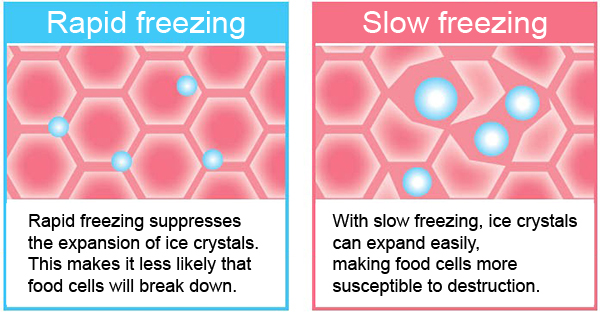

■Rapid freezing allows quality to be maintained while expanding the range of applications and objectives

Hoshizaki already sells blast chillers and shock freezers, which use cold air to freeze food. It has now newly developed liquid freezers that freeze foods with liquid ethanol at -35°C. As liquids have higher thermal conductivity than gases, they are able to freeze food faster. Rapid freezing prevents the maximization of the large ice crystals that are caused by slow freezing4. This curbs the destruction of food cells, reduces the outflow of umami components (drip) during thawing, and maintains the quality, texture, and freshness of the food.

Rapid freezing has extended the range of freezable foods. Foods with a high moisture content, which have previously been considered unsuitable for freezing, such as konjac, can now be frozen. Foods such as meat and fish have been subject to concerns about loss of quality when frozen, but rapid freezing has alleviated such concerns. This technology can be used in a variety of applications, regardless of the type of food industry. As such, it can be expected to deliver various types of prepared meals and to encourage the effective use of more foods, which will contribute to the reduction of food waste. In addition, restaurants and other foodservice businesses will be able to improve their operational efficiency with pre-cooking and short freezing times, allowing them to make more effective use of human resources. For example, staff with advanced cooking skills would prepare and cook meals for rapid freezing, with casual staff completing the final, simpler cooking steps before serving.

Comparison with konjac (left: rapid freezing, right: slow freezing)

Hoshizaki will continue to promote the development of products to meet market demands.

■Other features

●Small installation space: Exhaust space required on one side only, either left or right side; not required at rear

・Exhaust ports are located on the left, right, back, and underneath, so the unit takes up less space.

●Intuitive, well designed operation panel

●Fixable basket for straining above the liquid tank

・The movable handle on the strainer basket can be expanded, and the strainer can be fixed in place tilted over the liquid tank for ease of straining.

●The four included racks are removable, allowing for adjustment of height (up to five levels) of the racks within the basket.

●Dew heater with adjustable high/low settings

・Settings can be changed according to the operating environment and season, allowing for environmentally friendly, energy-efficient use.

■Product Overview

| Model | External dimensions (mm)5 | Freezing performance | Price |

|---|---|---|---|

| HLF-2A | W500 × D610 × H980 mm | 2kg/hour | Open price |

| HLF-3A | W500 × D610 × H980 mm | 3kg/hour | Open price |

1:Home-cooked meals: Meals prepared from ingredients at home; Prepared meals: Meals such as cooked foods, bento lunch boxes, ready-made foods, takeout, and delivery

2:Food Market Trends, “2023-Nenban Souzai Hakusho [2023 ready-made meal white paper]” Japan Ready-made Meal Association; Prepared meals fall under the ready-made meal market (CO2)

3: Statistical data prepared by Japan Frozen Food Association

4: Slow freezing refers to freezing food with the temperature at the core of the food item remaining within maximum ice crystal formation range (-5°C to -1°C) for more than 30 minutes. As water grows in volume while freezing, when food is frozen, the water inside changes into ice crystals, which increases the volume.

5: Depth measurement excludes the front handle of the top lid