IR News

Hoshizaki re-enters thawing cabinet market

with newly developed product

Warm-air thawing refrigerator meets recent needs of meat consumption market

HOSHIZAKI CORPORATION (Head office: Toyoake City, Aichi; President & COO: Yasuhiro Kobayashi; hereafter “Hoshizaki”) will re-enter the thawing cabinet market with a newly developed warm-air thawing refrigerator. The new product will be available through Hoshizaki’s sales companies from March 27, 2023.

Frozen foods: Increase in consumption, expectations for reduction of food waste

With improvements in quality due to advances in refrigeration technologies and the expansion of the cold chain, consumption of frozen foods is on the rise. Consumption in Japan reached a record high 2,946,949 tonnes in 2019, and has maintained that high level, with consumption in 2021 totaling 2,904,746 tonnes*1. Moreover, because frozen foods keep for longer, and it is possible to thaw only what is needed, they are expected to contribute to the reduction of food waste. Hoshizaki has a previous track record in the supply of thawing cabinets in the 1980s and 1990s. In response to recent changing market needs, Hoshizaki has been working on research and development of a new thawing cabinet since last year.

Newly developed warm-air thawing refrigerator: Preserving the flavor of meat with specialized thawing equipment

There is firm demand for meat in Japan. According to Ministry of Agriculture, Forestry and Fisheries statistics, annual per capita meat consumption in Japan reached a record high 33.8 kg*2 in FY2021. The optimal thawing method differs depending on what is being thawed, its shape, and its packaging. Hoshizaki has developed a warm-air thawing refrigerator that is perfect for thawing vacuum-packed meat.

Conventional methods of thawing vacuum-packed meat, such as in the refrigerator, under running water, or at room temperature, each have their own problems with causing a decline in the flavor of the meat, due to issues with time control, taking up sink space, and over-thawing respectively. These problems can all be solved with the introduction of a specialized thawing refrigerator. Primarily, Hoshizaki will target restaurants, supermarkets, and other businesses that use the hours after closing to thaw out large quantities of meat overnight for the next day.

In addition to pursuing the research and development of thawing technology to meet market needs, Hoshizaki plans to expand its line-up of thawing refrigerators going forward.

Main features

・Uniform temperatures in the cabinet reduce thawing inconsistencies

A unique duct construction, in which a total of four ducts are placed on both sides of the cabinet, allows uniform control of the temperature inside the cabinet, which reduces thawing inconsistencies and maintains the flavor of the food.

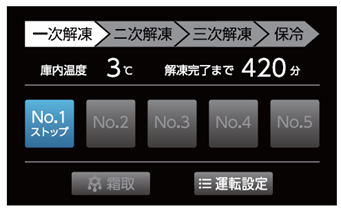

・Touch panel

The intuitive controls are easy for anyone to operate, and the operational status can be seen at a glance.

・3-step thawing

One thawing program can be set with up to three steps, combining different thawing temperatures and times. Fine adjustments to settings allow the user to choose the ideal thawing temperature and time for each food. Up to five programs can be saved.

・Capacity that makes the most of the cabinet volume

The product has a single cabinet with one long door, allowing for storage space that makes the most of the cabinet’s volume.

HD-63A

*1 Trends in Domestic Consumption, Japan Frozen Food Association

*2 Total of annual per capita consumption figures for beef, pork, and poultry in the Food Supply and Demand Table, Ministry of Agriculture, Forestry and Fisheries, Japan

Product Specifications

| Model | HD-63A |

|---|---|

| Power Supply | Single phase 100V 50/60Hz |

| Number of Shelves | 7 (+ 1 Bottom shelf) |

| External Dimensions | W 625 mm x D 800 mm x H 1,910 mm |

-

Unique duct construction (Side ducts)

-

Touch panel screen